HOME › Products › Continuous Automatic Weighing System › Uni-Auto Feeder (UEL Series)

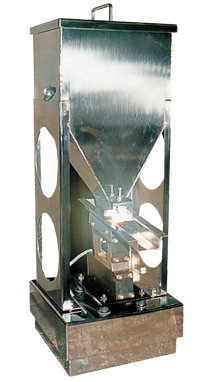

Uni-Auto Feeder (UEL Series)

By using a loss-in-weight method, this feeder guarantees stable and accurate performance. This series can improve yield, stable quality, and improve workability for multiple-model and small quantity production systems.

- Registered patents

- No.1829305

No.1632668 - Registered model utilities

- No.1806281

No.1990516

List of standard functions

Coil feeder-type (CF) / Screw feeder-type (SF)

The coil-driven system or screw-driven system may be selected for the same main unit.

Coil feeder-type (CF)

This CF type feeds material by coil drive and is suitable for a wide range of materials, such as pellets, powdery material,fibrous or flaky material.

| Type | Capacity (l/h) | Hopper capacity (l) | Motor used | Power source |

|---|---|---|---|---|

| CF-32 | 200~10 | 40 | 400W | AC200V 50/60Hz |

| CF-65 | 1,100~20 | 200 | ||

| CF-80 | 2,400~110 | 400 |

*In addition to the above, we also manufacture large-scale CF-100 (Capacity: 7,000-700 l/h) and CF-125 (capacity: 14,000-1400 l/h)

Screw feeder-type (SF)

This SF type feeds material by one axial screw drive and is suitable for a wide range of materials, such as granules or flaky material.

| Type | Capacity (l/h) | Hopper capacity (l) | Motor used | Power source |

|---|---|---|---|---|

| SF-32 | 140~5 | 30 | 400W | AC200V 50/60Hz |

| SF-65 | 1,500~45 | 300 | ||

| SF-80 | 2,900~290 | 500 | 750W |

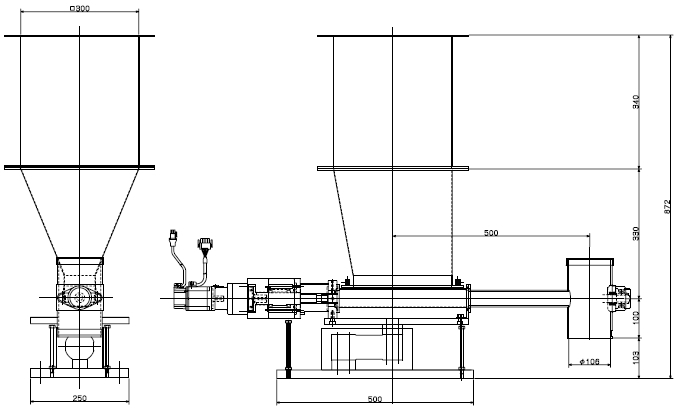

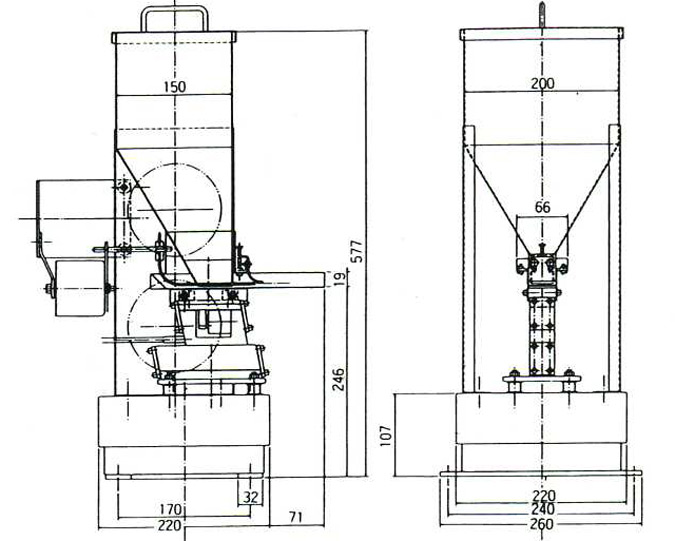

*The drawings below show CF-32 (SF-32).

Twin screw feeder-type (WF)

This WF type feeds material by a self-cleaning function of twin screw and is suitable for sticky materials as well as pellets and granules.

| Type | Capacity (l/h) | Hopper capacity (l) | Motor used | Power source |

|---|---|---|---|---|

| WF-15 | 50~0.5 | 5 | 100W | AC200V 50/60Hz |

| WF-35 | 500~5 | 70 | 400W | |

| WF-40 | 800~20 | 120 | ||

| WF-50 | 2,000~50 | 400 | 750W |

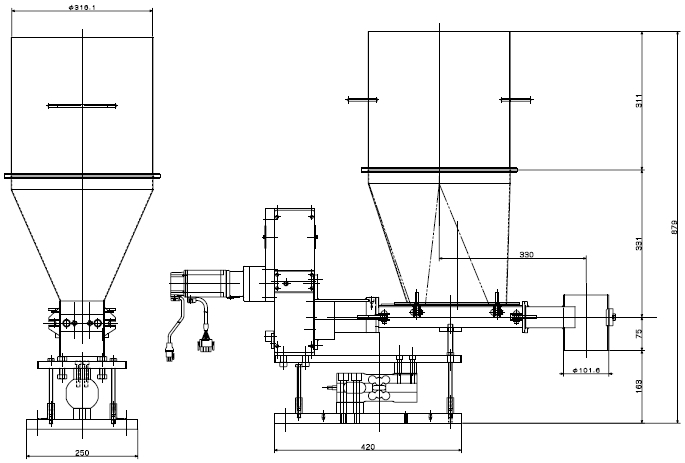

*The drawings below show WF-15.

Belt feeder-type (BF)

This BF type feeds material by belt drive, and controls the belt speed according to the bulk density of material. These feeders are suitable for various materials, such as powder, fibers or flakes.

| Type | Capacity (l/h) | Hopper capacity (l) | Motor used | Power source |

|---|---|---|---|---|

| BF-151 | 50~5 | 20 | 100W1/30 | AC200V 50/60Hz |

| BF-201 | 150~15 | 60 | 400W1/30 | |

| BF-401 | 900~90 | 150 | 750W1/30 |

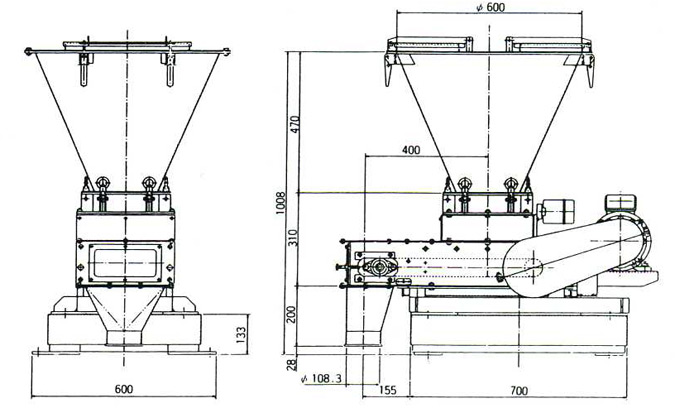

*The drawings below show BF-201.

Vibratory feeder-type (VF)

This VF type feeds material by micro-vibration, and suitable for powdery material, fibrous or flaky material.

| Type | Capacity (l/h) | Hopper capacity (l) | Power source |

|---|---|---|---|

| VF-01A | 10~2 | 3.5 | AC200V 50/60Hz |

| VF-01B | 25~5 | 10 | |

| VF-01C | 50~10 | 30 | |

| VF-11A | 100~20 | ||

| VF-11B | 200~40 | 80 |

*The drawings below show VF-01A.

Control Unit LC-5500

This is a new high-performance unit that fully brings out the capabilities of the feeder. It comes equipped with clear and prominent digital displays. Making settings is easy and secure while viewing the display. All the information needed for continuous measurement have been integrated in this compact unit. The standard control panel is a compact wall-mounted type.

Specifications

- Type: LC-5500

- Analog section

- Zero-span adjustment and fully automatic adjustment

- Accuracy (linear): 0.01%/FS

- A/D converter: high-speed, high-resolution ratiometric system

- Display section

- Weight display: 5-digit (high-intensity fluorescent display lamp)

- Instant conveying volume display: 5-digit (high-intensity fluorescent display lamp)

- Settings and warning display: 20 characters x 2 rows (character display lamp)

- Status display: LED display lamp

- Setting section

- Setting device: membrane keys with key clip buzzer

- Setting method: Function key + ten-key

- Storage of setting values: E2-ROM (non-volatile) S-RAM (with backup battery)

- Option: CCLINK interface