HOME › Products › Hopper Scale Weighing System › Small Quantity Weighing System HBS

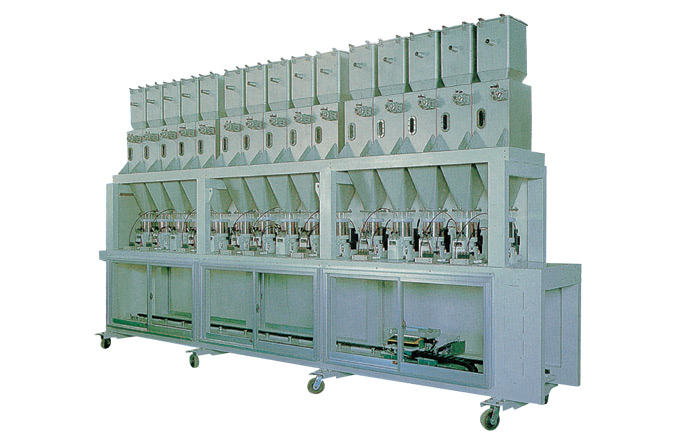

Small Quantity Weighing System HBS

For small-volume production of variety of products,Suitable for blending and weighing of dying/pigment.

- Relization of milligram-order precision regardless of batch size

- The system can handle a wide range of batch sizes, in scales from milligrams to kilograms,with guaranteed precision on the milligram order.

- Compatible with various powder types

- Various types of feeders are available,such as the twin-screw feeder with a self-cleaning mechanism, coil feeder,table feeders, etc., allowing the system to maintain stable feeding conditions even for materials having high flushing or adhesion properties.

- Unmanned Automatic weighing

- The feeding, weighing, dispatching, and shipping processes are fully automated and require no manual operation.

- Immediate switchover to different products

- The feeder unit is fixed with a snap-on clamp to allow for easy dismantling and cleaning, and also provides for the switching of raw materials without interruption in operation.

- User-friendly controls

- The LC-1500/5500 control unit can be detached from the mainbody for remote control of the system. Up to 99 product types may be registered,and by presetting the tank number, weight, and pre-weighing conditions, automatic operation may be initiared simply by inputting the product neme. The various settings mey be made and confirmed while viewing the touth-key and rotaryencoder displays.

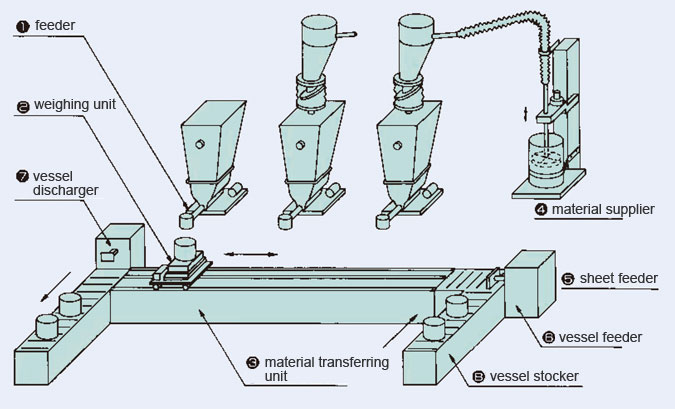

Basic system configuration diagram

Weighing Method

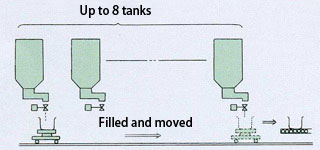

Simple additional weighing

When the cumulative total is within the limit of the weighing range of the scale

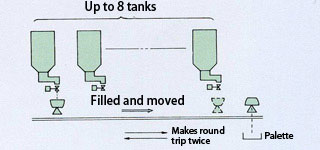

Duplicated Accumulation Weighing

When the palette is fixed and the cumulative total weight is within double the weighing range

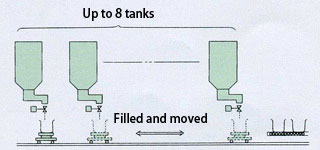

Number of times weighing

When weighing is repeated several times if the cumulative total weight exceeds the upper limit of the weighing range of the scale

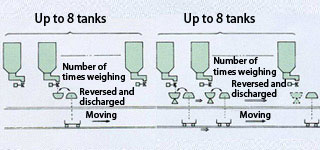

Complex Weighing

When the palette shifts in synchronization with the scale and weighing is done a number of times from the designated tank, or when the cumulative total weight is over double the upper limit of the weighing range of the scale

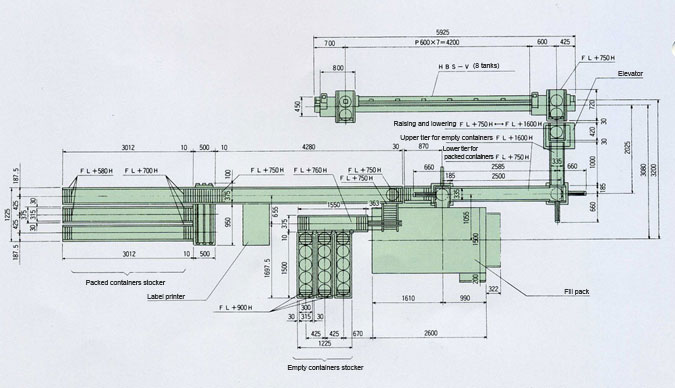

System drawing

Major Specifications

| 1 | Type | HBS | ||

|---|---|---|---|---|

| 2 | Model | HBS-H | HBS-R | HBS-V |

| 3 | Weighting range(Upper limit) | 100kg~10kg | 6kg~2kg | 50kg~4kg |

| 4 | Minimum indication(Graduation) | 50g~2g | 1g~0.5g | 1g~0.1g |

| 5 | Capacity | 3min.at8tanks4kinds additional measurement | ||

| 6 | Tank configuration | 4tanks 6tanks 8tanks | ||

| 7 | Accurary | 1% to setting value | ||

| 8 | Feeder | Single screw feeder,twin screw feeder, coil screw Feeder, vibratory feeder,etc. | ||

| 9 | Weight detector | Load cell | Load cell | Electronic balance |

| 10 | Material feeder | We'll provide it on your request | ||

| 11 | Cap. of stock tank | 50 |

||

| 12 | Brand setting | Max.99 kinds | ||

| 13 | Setting type | Rotary encoder | ||

| 14 | Weight vehicle | Reciprocating | ||

| 15 | Unloaded | Option | ||

| 16 | Dust collecting hood | Standard | ||

| 17 | Option |

|

||

| 18 | Power source | Instrumentation AC100V 50/60Hz power AC200V 50/60Hz | ||

*1 at simple additional weighting method

*2 duct collector is option