HOME › Products › Packer Scale - Automatic Packaging System › Servo Packer Scale

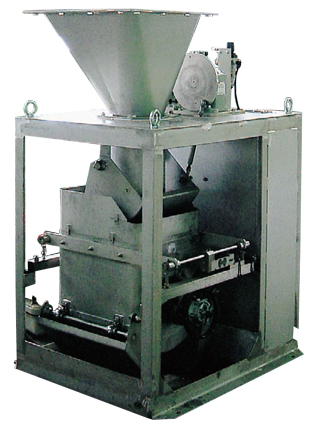

Servo Packer Scale

Servo Packer Scale PSL-300

Features

- High capacity with servo motor control.

- The gate control uses a servo motor enabling throw-in at a high speed, making possible the high rate of 400 to 600B/H. Easy touch panel operation allows the gate opening angle to be set to suit what is being weighed.

- Precitsion and high speed feeling by integrated load cell installation.

- The load detection section features unique load cells that receive loads directly at two points. This eliminates fluctuation and distortion of the weighing hopper, and prevents excessive loads. As a result, stable high performance and accuracy are guaranteed all the time.

- Simple and easy maintenance with newly developed control unit.

- The single gate makes the structure simple, allowing easy maintenance and cleaning.

Main specifications

| Designation | PSL-300(servo packer) | ||

|---|---|---|---|

| Type | Single | Double | |

| Measuring quantity | 20~30kg | ||

| Accuracy | ±1/1000~±1/2000 | ||

| Capacity | 400~600B/H | 800~1,200B/H | |

| Material to be weighed | Pallet,fluidal like pallet, granule, fertilizer | ||

| Weighing method | Load cell type(2 points) | ||

| Feeder | Single cut gate | ||

| Hopper capacity | 50~120 |

||

| Power source | AC200V 50/60Hz 3 phase 1.5KVA(single) |

||

| Air source | 0.490MPa(5kgf/cm2) | ||

| Air consumption | 50 |

100 |

|

| Dust collection | Vacuum pressure | 200~300mmAq | |

| Air | 5~6m3/min | 10~12m3/min | |

| Own weight | about 500kg | about 950kg | |

| Painting color | Munsell 5Y7/1 | ||

| Standard components (In case of using LC-1500) |

|

||

| Option |

|

||

Servo Packer Scale PSL-100V・PSL-100SF

Features of PSL-100V

- Speedy feeding by adopting a combination of cut gate and electromagnetic feeder.

Features of PSL-100SF

- Smooth and speedy feeding by screw feeders.

Features Common to PSL-100V and PSL-100SF

- High performance and accuracy.

- The load detection section receives loads directly in the load cells at two points, eliminating fluctuation in the weighing hopper and guaranteeing high performance and accuracy.

- Free from bridging. Shorten charging time.

- The weighing hopper is a drum-type with a flap gate mechanism that opens and closes both ways, preventing the bridge phenomenon and reducing discharge time.

Main specifications

| Designation | PSL-100V | PSL-100SF | ||||

|---|---|---|---|---|---|---|

| Type | Single | Double | Triple | Single | Double | |

| Measuring quantity | 20~50kg | 20~50kg | ||||

| Accuracy | ±1/1000 | ±1/1000 | ||||

| Capacity | 200~400B/H | 400~800B/H | 700~1,200B/H | 150~200B/H | 200~400B/H | |

| Material to be weighed | Super fine~granule | Super fine etc. | ||||

| Weighing method | Load cell type(2 points) | Load cell type(2 points) | ||||

| Feeder | Cut gate and electromagnetic feeder | Screw feeder | ||||

| Hopper capacity | 50~120 |

50~120 |

||||

| Power source | AC200V 50/60Hz 3 phase 1.5KVA(single) |

AC200V 50/60Hz 3 phase 3KVA(single) |

||||

| Air source | 0.490MPa(5kgf/cm2) | 0.490MPa(5kgf/cm2) | ||||

| Air consumption | 50 |

100 |

150 |

50 |

100 |

|

| Dust collection | Vacuum pressure | 200~300mmAq | 200~300mmAq | |||

| Air | 5~6m3/min | 10~12m3/min | 15~18m3/min | 5~6m3/min | 10~12m3/min | |

| Own weight | about 500kg | about 950kg | about 1500kg | about 600kg | about 1200kg | |

| Painting color | Munsell 5Y7/1 | Munsell 5Y7/1 | ||||

| Standard components (In case of using LC-1500) |

|

|

||||

| Option |

|

|

||||