HOME › Products › Recycle System › PET Bottle Compressor PB Series

PET Bottle Compressor PB Series

PET Bottle Compressor PB Series

Recommended by Council for PET Bottle Recycling

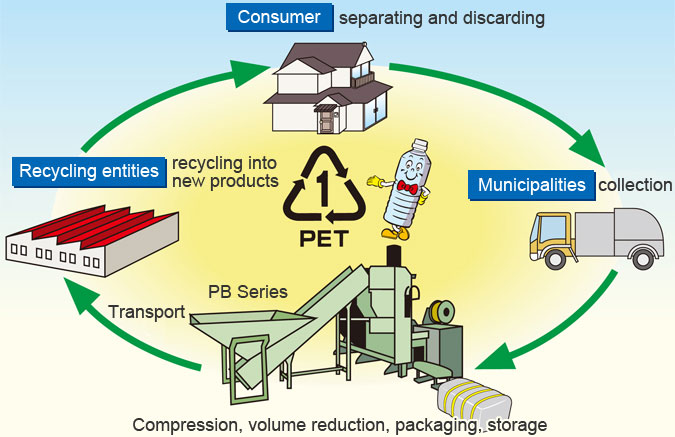

Recycling has been mandated for PET bottles under the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging that was enacted on April 1, 1997.

The PB Series PET bottle compressors of KAMACHO have achieved sales of over 200 units since their release. They compress and reduce the volume of PET bottles collected from general households, and bind them with PP bands. They are effective for reducing workloads when transporting to the next processes, and also for reducing costs.

Role of the PB Series in Recycling

Features

- PET bottles are compressed, volume-reduced and packaged automatically just by throwing them into the hopper.

- The volume of PET bottles is reduced to about 1/10, allowing for a reduction in transportation costs.

- Equipped with a built-in piercing mechanism for handling capped bottles.

- A wide range of optional functions are available.

- Status display screen

- The LCD display enables operation status to be viewed at a glance.

- Automatic scale

- The number of bails being processed and cumulative weight are displayed and printed. (Utility model)

- Processing of containers and packaging other than PET bottles

- Paper packs for milk and other products and plastic trays can also be processed.

Major specifications of standard types

| Item/Type | PB1000 | PB800 | PB500 | PB400 | PB300 | PB200 | PB100 | PB100T |

|---|---|---|---|---|---|---|---|---|

| Processing capacity: kg/h | 1000 | 800 | 500 | 400 | 300 | 200 | 100 | 100 |

| Bail dimensions (mm) | 600×600×400 | 600×400×350 | 600×400×300 | |||||

| Bail weight (kg) | 30~40 | 15~20 | 13~18 | |||||

| Binding method | PP band: automatic | Semi-automatic | ||||||

| Motor (kW) | 37 | 30 | 22 | 15 | 7.5 | 5.5 | 3.7 | 3.7 |

| Compression force (kN(t)) | 411(42) | 316(32) | 275(28) | 242(24) | ||||

| Surface pressure (MPa) | 1.14 | 1.3 | 1.14 | 0.98 | ||||

| Piercing mechanism | Included | |||||||

| Voltage | AC 200V 50/60Hz | |||||||

| Weight (kg) | Approx. 7,000 | Approx. 4,500 | Approx. 3,500 | Approx. 2,500 | ||||

| Options |

|

|||||||

*The processing capacity may vary depending on the apparent relative density of the PET bottles collected.

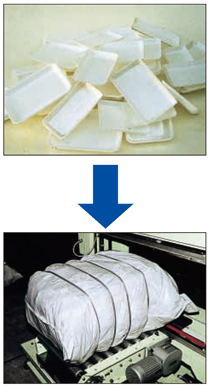

Examples of compressed containers with reduced volumes

PET bottles

Paper packs for milk and other products

Plastic trays

*Type for processing PET and other plastic containers

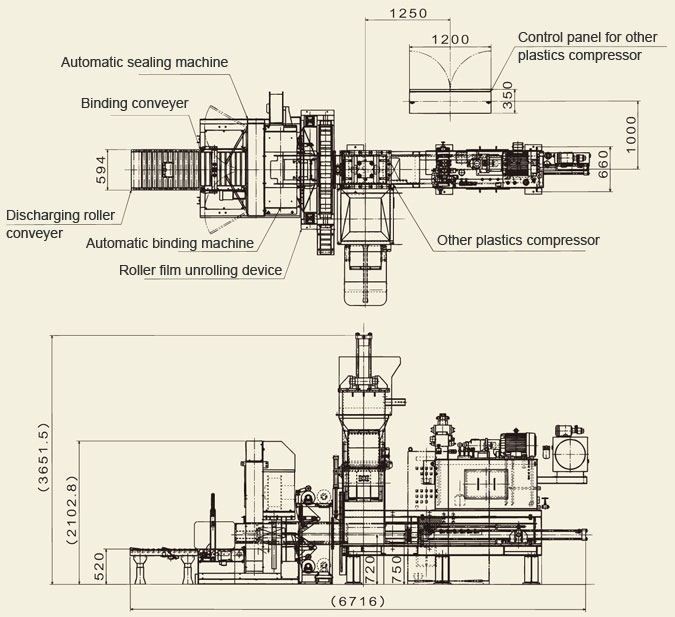

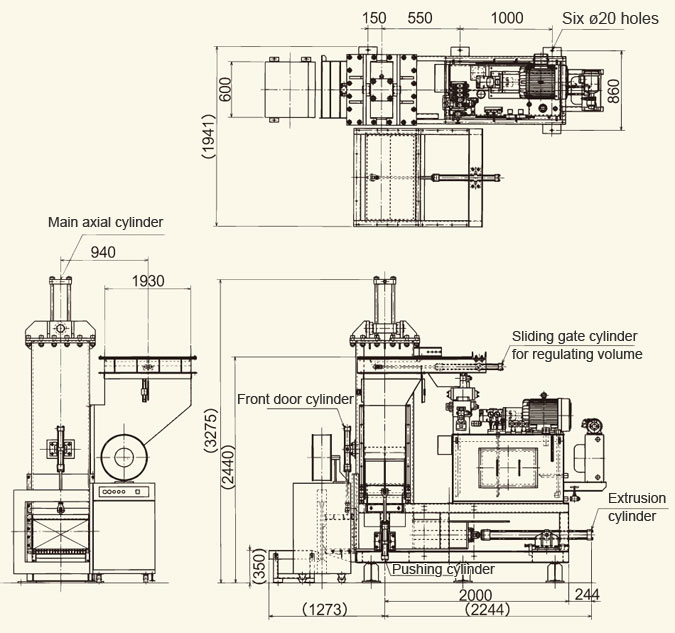

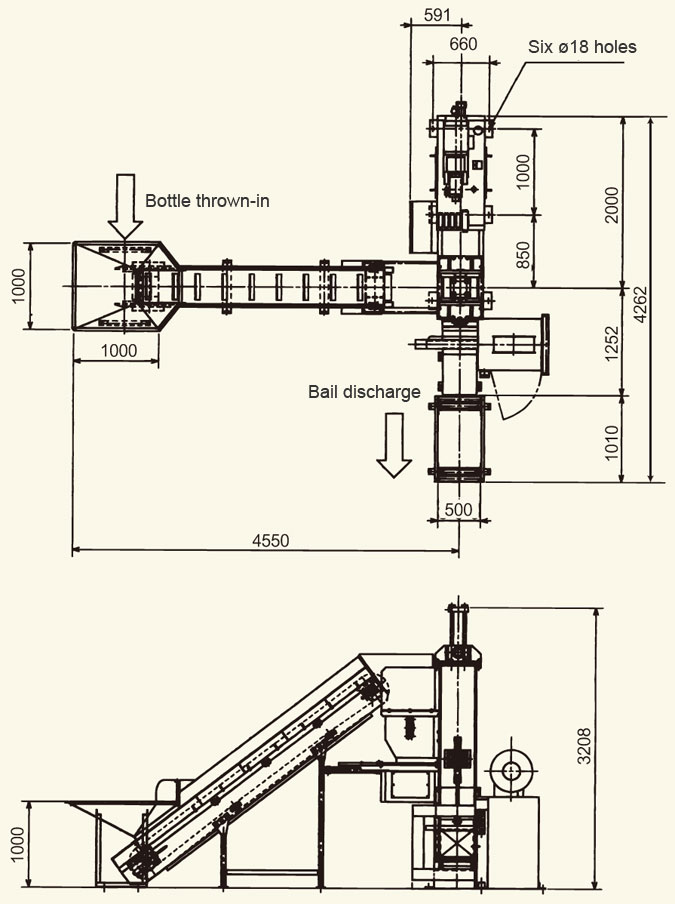

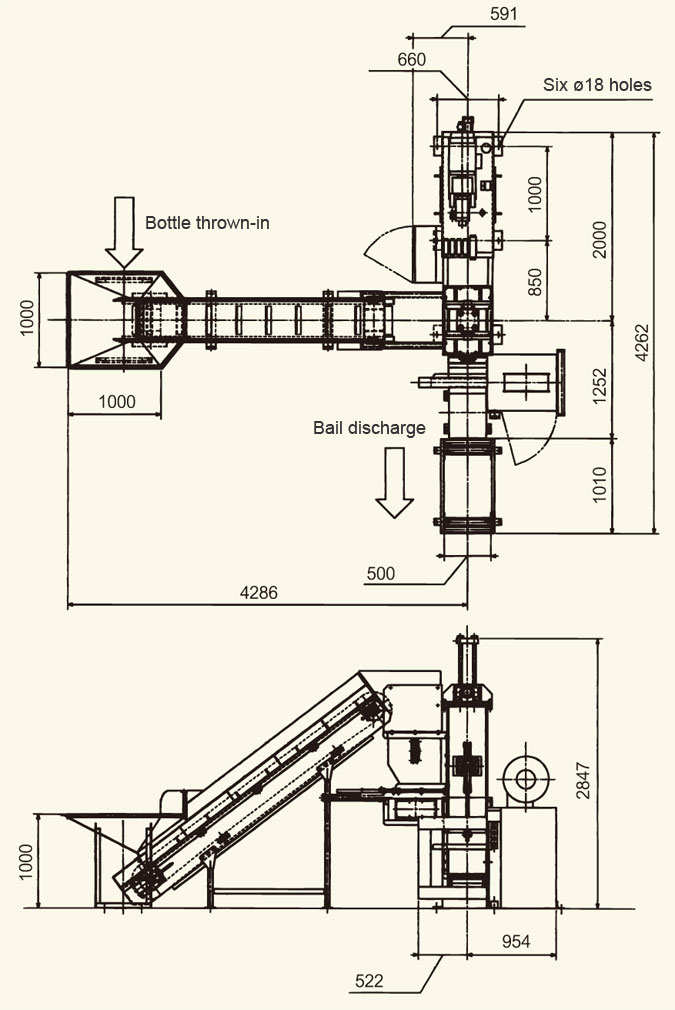

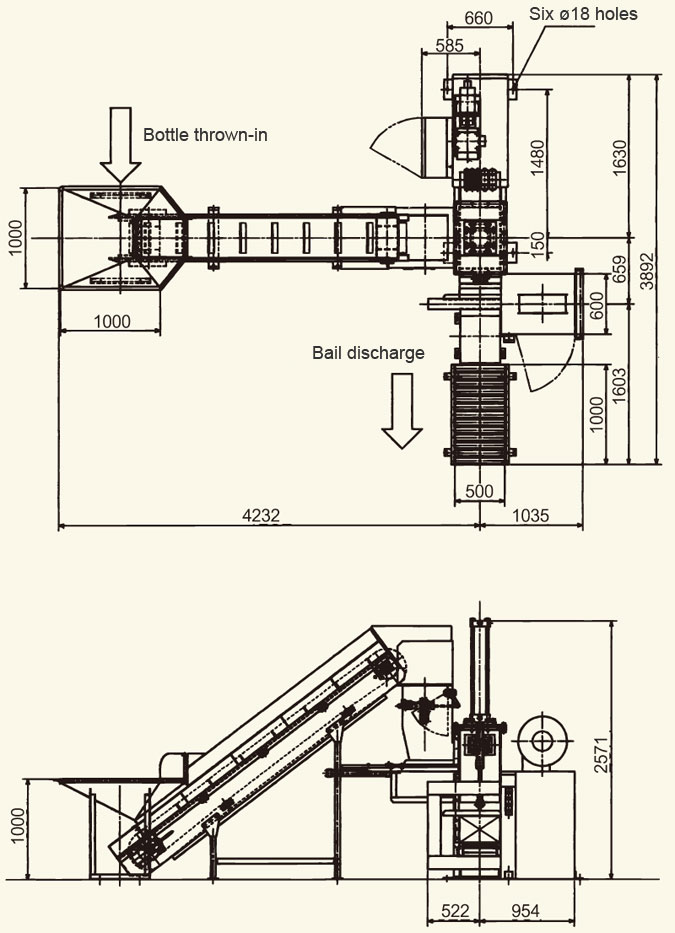

External Drawings

*Conveyers for manual sorting before processing may also be added.

PB-1000・800

PB-500・400

With conveyer for throw-in

PB-300・200

With conveyer for throw-in

PB-100

With conveyer for throw-in and gate for preventing bridging

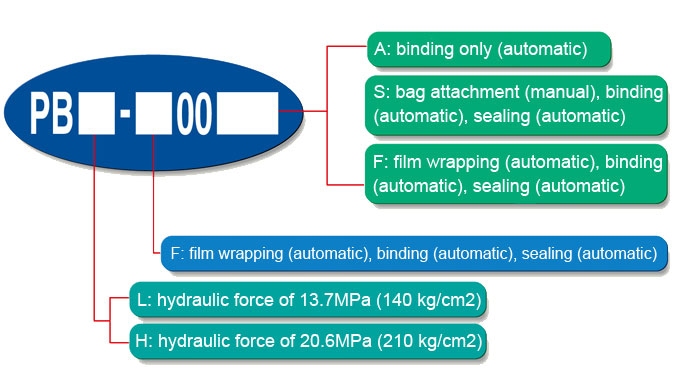

Type for Processing PET and Other Plastics (PBL, PBH)

- Compresses, reduces volume and binds other plastics (A type)

- Wrapped with in film, sealed, and bound for preventing fall-off and odor (S type and F type)

Various combinations are possible to suit your purposes and applications.

Please select as shown below.

Binding and sealing section

- PET bottles and other plastics are processed separately.

- Other plastics are thrown in loose or after packing in a small bag (about 30 liters or less).

- Filled bags larger than 30 liters are thrown in using the manual throw-in chute.

- The processing capacity for other plastics is 70% that of PET bottles and 20% or less for plastic trays.

External drawings for PBL (H)-F