HOME › Products › Packer Scale - Automatic Packaging System › Flexible Container Packer Scale

Flexible Container Packer Scale

- Flexible Container Packer Scale FB-W

- Flexible Container Packer Scale FB-WL

- Flexible Container Packer Scale FB-A

- Flexible Container Packer Scale FB-D II

- Flexible Container Round Packer Scale FB-R

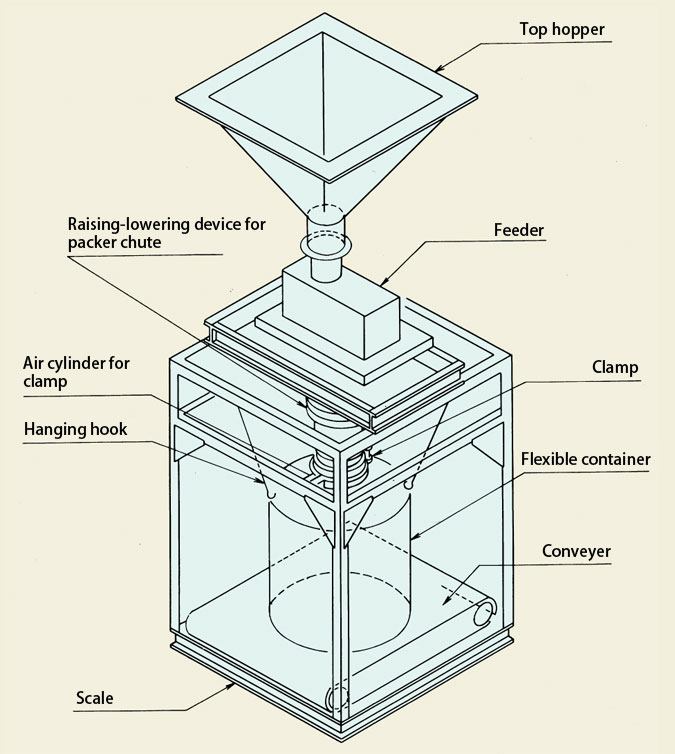

Flexible Container Packer Scale FB-W

Features

- Easy Installation

- The weighing section, packing section and control section are separate units, and the packer scale can be used just by connecting them at the site. It can be moved easily with a lift truck, and installed with existing feeders easily.

- Highly Accurate Packing

- Uses highly accurate load cells with nonlinearity of +/-0.03%.

- Easy Maintenance

- The structure is simple, and loads are detected by load cells, so almost no maintenance work is necessary.

Flexible Container Packer Scale Mechanism

Major Specifications

| Designation | FB-W |

|---|---|

| Packed quantity | 250~1,000kg |

| Capacity | For CG supply: 30B/H For SF supply: 20B/H |

| Accuracy | ±1/500~±1/1000 |

| Materials to be weighed | Powders, granules |

| Power source | AC100V or AC200V |

| Air source | 0.490MPa(5kgf/cm2)~ |

| Air consumption | 200 |

| Flexible container specifications |

One-way bag PVC and rubber bags |

| Type |

|

| Options |

|

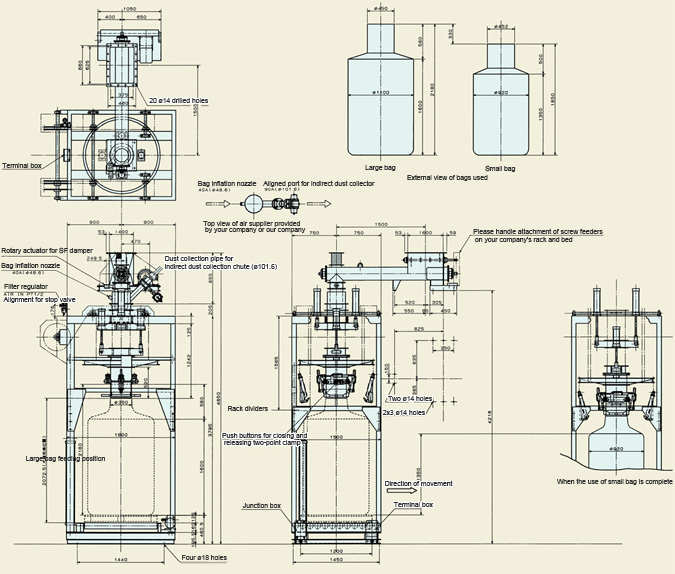

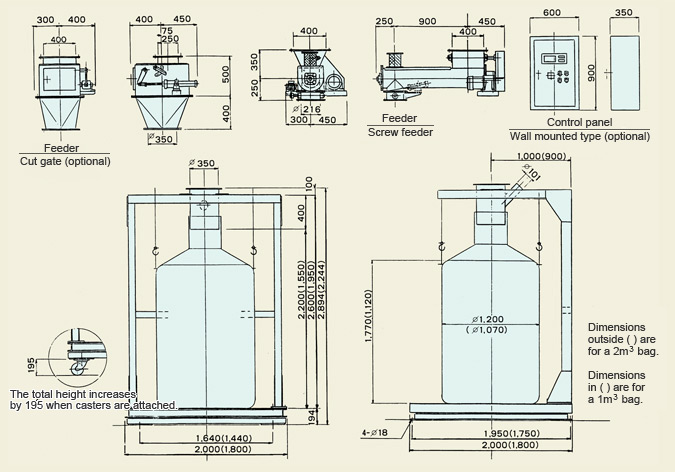

External view

Flexible Container Packer Scale with Palette Magazine

Best for streamlining the process and saving energy when shipping flexible containers

This system enables palettes to be fed automatically when attached to a flexible container packer scale, which significantly facilitates the use of a forklift to remove automatically weighed (packed) bags. The system can be set up easily with existing flexible container packers. It greatly helps streamlining the process and saving energy when shipping flexible containers.

Flexible Container Packer Scale FB-WL

Features

- Low Facility Costs

- Since the equipment height is low, the costs for auxiliary facilities can be reduced.

- Easy Installation and Moving

- The weighing section, packing section, and control section are separate units, and the packer scale can be used just by connecting it at the site.

Free-standing roller conveyers are optionally available.

Major Specifications

| Designation | FB-WL |

|---|---|

| Packed quantity | 250~1,000kg |

| Capacity | For CG supply: 30B/H For SF supply: 20B/H |

| Accuracy | ±1/500~±1/1000 |

| Materials to be weighed | Powders, granules |

| Power source | AC100V or AC200V |

| Air source | 0.490MPa(5kgf/cm2)~ |

| Air consumption | 50 |

| Flexible container specifications | One-way bag PVC and rubber bags |

| Type |

|

| Options |

|

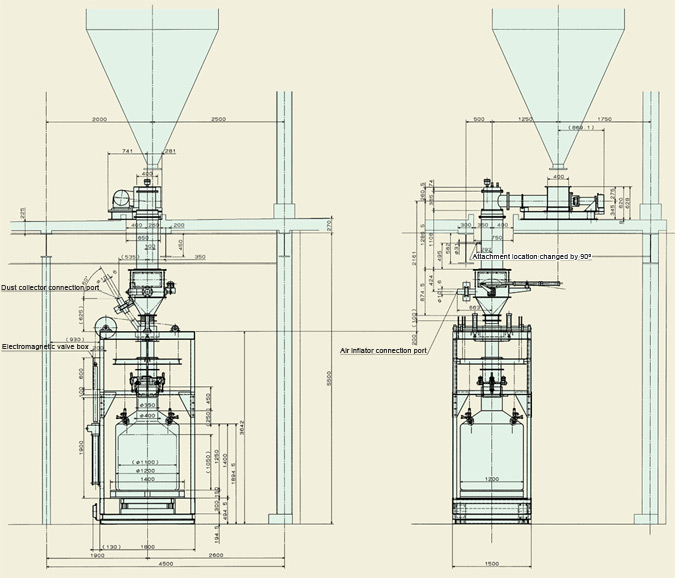

External view

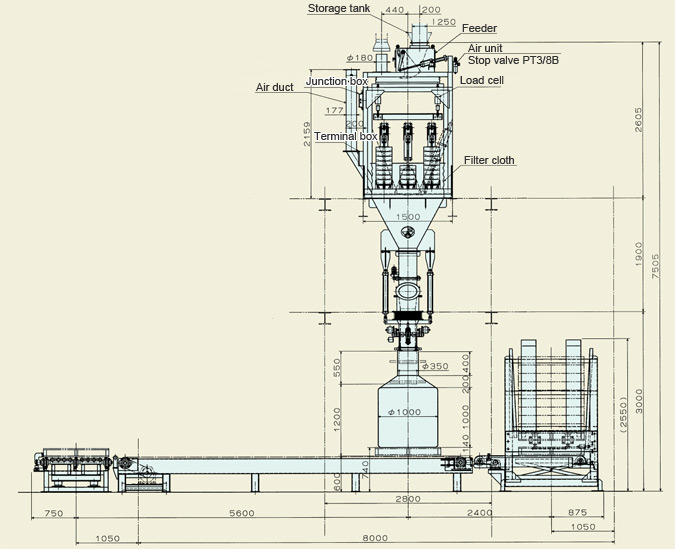

Flexible Container Packer Scale FB-A

Features

- High accuracy and performance

- High performance realized by combining with an automatic hopper scale.

Major Specifications

| Designation | FB-A |

|---|---|

| Packed quantity | 250~1,000kg |

| Capacity | 60~80B/H |

| Accuracy | ±1/500~±1/1000 |

| Materials to be weighed | Powders, granules |

| Power source | AC100V or AC200V |

| Air source | 0.490MPa(5kgf/cm2)~ |

| Air consumption | 200 |

| Flexible container specifications | One-way bag PVC and rubber bags |

| Type |

|

| Options |

|

External view

Flexible Container Packer Scale FB-D II

Features

- Deaeration and pressurization are done when the flexible container is packed, thereby realizing optimum density.

- The system is optimum for fine powders with the appearance of low relative density and materials with large air content that take time settling naturally.

Major Specifications

| Designation | FB-D II |

|---|---|

| Packed quantity | 100~1,000kg |

| Capacity | To be discussed after deaeration test |

| Accuracy | ±1/500~±1/1000 |

| Materials to be weighed | Fine powders |

| Scale section |

|

| Feeder |

|

| Deaeration device | Vacuum deaeration using special multiple-pore filter |

| Flexible container packer |

|

| Control device |

|

| Options |

|

External view

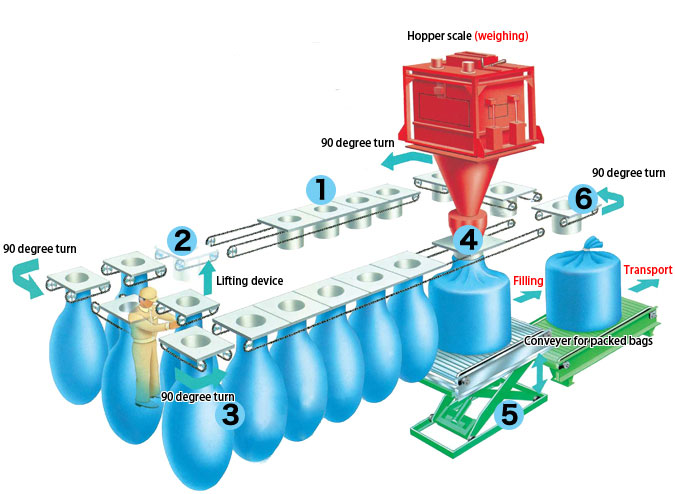

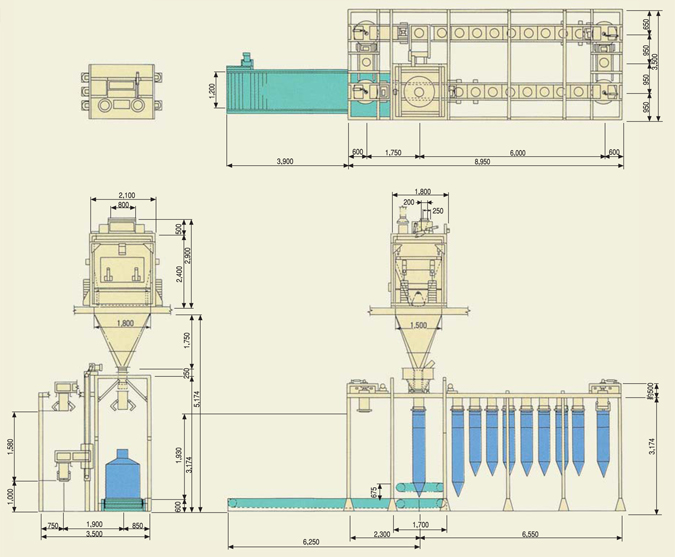

Flexible Container Round Packer Scale FB-R

Features

- Conventional bags may be used, since the packer scale is compatible with a wide range of bag dimensions and materials.

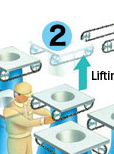

- High performance made possible because bags are fed, weighed, packed, and carried out in succession, eliminating unnecessary movements found in conventional systems.

- Bags are handled continuously instead of the conventional process of being handled one by one by a large number of people, so labor and energy can be reduced.

- Net measurement is the standard, but gross measurement is also possible. The system can be assembled using existing hopper scales.

- Bag inflation device can be added. (for inner-poly bags)

- Palettes may or may not be used, and setting up is easy with palette magazines.

- The position of the scale and empty bag supplier can be changed freely. The position of the conveyer to bring out packed bags can also be changed.

- The standard number of bags in the empty bag pool is 15, but this can be changed depending on arrangements.

Major Specifications

| Designation | FB-R |

|---|---|

| Packed quantity | 500kg、1,000kg |

| Capacity | 60B/H~80B/H |

| Materials to be weighed | Powders to pellet |

| Power source | AC200V±10% 50/60Hz 8kVA |

| Air source | 0.490~0.686MPa(5~7kgf/cm2) |

| Air consumption | 200 |

| Clamp position | Quantity: 15 (standard) |

| Feeder | Periferal clamps |

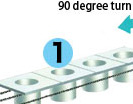

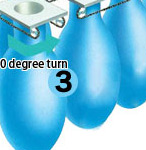

| Turning device | Air cylinder-driven turning (90 degrees) With geared motor-driven chain conveyers |

There are two types: round and linear

External view

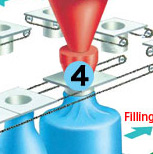

Net quantity weighing method

Operation diagram

Click the section you wish to see.

Control panel

This is the heart of the system, with total control of the entire system.