HOME › Products › Recycle System › Other Plastics Compressor PL Series

Other Plastics Compressor PL Series

This equipment is a compressor and packer for plastic containers and packing (excluding PET bottles), which conforms to the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging. It's comprised of an upper hopper, compressor, roll film packer, binding machine, sealing machine and other parts, for automatically compressing and packing plastics.

Horizontal Compressor

Features

- Double packaging with PE film packing and PP band binding

Scattering of small containers and filthy drippage are prevented at the time of compression and packing, and the working environment is improved by containing odor with film packing. (Patented)

Compression and packing enhances loading efficiency at the time of storage and transport. - Equipped with compression, packing and density control and weighing functions

Since the properties of the materials to be processed are not uniform, the density control function enables the bail density to be set.

The scale can be used for totaling the number of bails, weight, and the volume processed. - Equipped with monitor for easy operation

The control panel is equipped with a monitor that displays operation status and bail weights, which along with the failure diagnosis function, makes operations easier and eliminates maintenance. - Roll film can be replaced easily.

- Packaging material costs can be significantly reduced.

Major Specifications

PL Series

| Capacity | 500kg/h | 1,000kg/h | 2,000kg/h | 3,000kg/h | 4,000kg/h | 5,000kg/h | |

|---|---|---|---|---|---|---|---|

| Type | |||||||

| Horizontal compression | Binding using PP bands only | PL-500A | PL-1000A | PL-2000A | PL-3000A | PL-4000A | - |

| Bag feeding (manual) + binding | PL-500S | PL-1000S | PL-2000S | PL-3000S | PL-4000S | - | |

| Film packing (automatic) + binding | PL-500F | PL-1000F | PL-2000F | PL-3000F | PL-4000F | - | |

| Vertical compression | Binding using PP bands only | - | - | PL-2000V-A | PL-3000V-A | PL-4000V-A | PL-5000V-A |

| Bag feeding (manual) + binding | - | - | PL-2000V-S | PL-3000V-S | PL-4000V-S | PL-5000V-S | |

| Film packing (automatic) + binding | - | - | PL-2000V-F | PL-3000V-F | PL-4000V-F | PL-5000V-F |

Specifications of horizontal compressor

| Type | PL-500 | PL-1000 | PL-2000 | PL-3000 | PL-4000 | |

|---|---|---|---|---|---|---|

| Compression method | Hydraulically-driven one-directional horizontal compression | |||||

| Dimensions of formed product | Approx. 600 wide x 600 long x 430 high (mm) | Approx. 1,200 wide x 1,000 long x 1,000 high (mm) | ||||

| Weight of formed product | Approx. 40-50kg each | Approx. 250-300kg each | ||||

| Compression force | MAX313kN(32ton) | MAX648kN(66ton) | ||||

| Surface pressure | MAX1.3MPa(13.3kgf/cm2) | MAX0.6MPa(6.6kgf/cm2) | ||||

| Processing capacity | 0.5t/h | 1t/h | 2t/h | 3t/h | 4t/h | |

| Hydraulic pressure | MAX20.6MPa(210kgf/cm2) | |||||

| Electric voltage | 3ØAC200/400V | |||||

| Engine for hydraulic unit | One 18.5kW unit | One 30kW unit | One 37kW unit | One 37kW unit | One 45kW unit | |

| Oil cooler pump | 0.75 | 0.75 | 1.5 | 1.5 | 3.7 | |

| Oil cooler fan | 0.2 | 0.2 | 0.4 | 0.4 | 0.75 | |

| Packing specifications | Packing in rolled polyethylene film + binding using PP bands | |||||

Note 1: The dimensions and weight of bails differ after being formed depends on the materials processed. Note 2: The processing capacity was calculated assuming the apparent densitiy of collected materials to be 0.03 ton/m3. The density of bails after compression is 0.25 to 0.3 tons/m3.

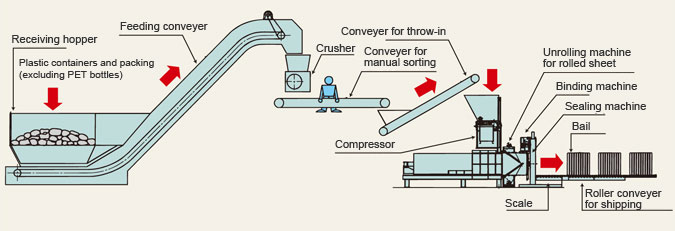

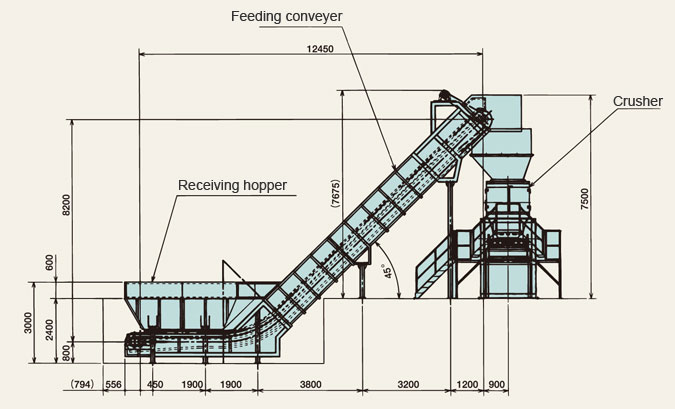

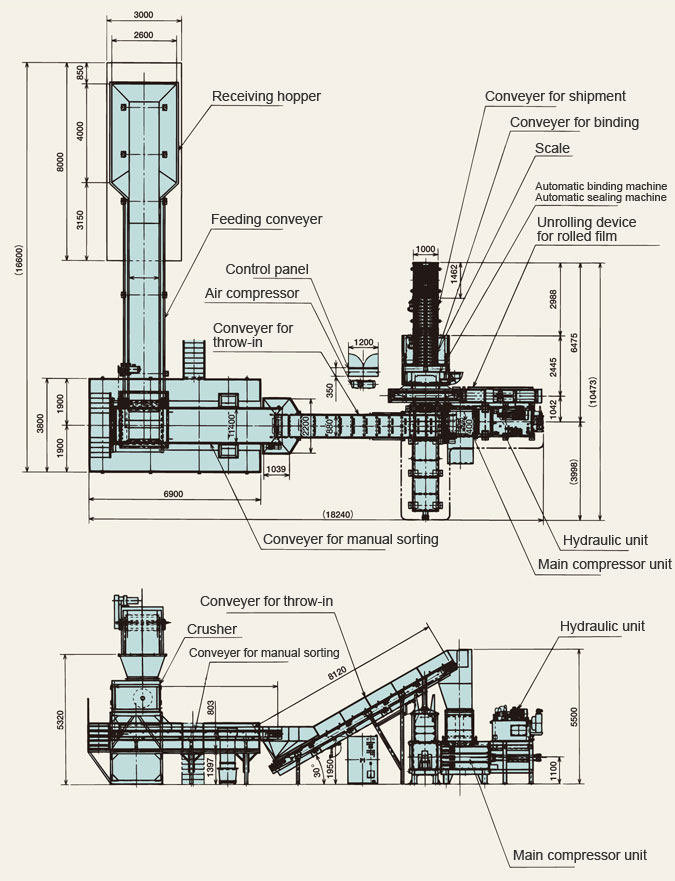

PL-3000F Example of delivered system

1. Receiving hopper and feeding conveyer

2. Feeding conveyer and crusher

3. Conveyer for manual sorting

4.Compression and volume reduction

5.Unrolling of rolled sheet

6.Packing, binding and weighing

7.Heat sealing

8.Bail discharge

Process flow sheet

Equipment layout

Vertical Compressor

Features

- The necessary installation space is small, making installation planning easier. This merit is especially significant when two units are installed in parallel.

- High-performance processing is possible by equipping with a preliminary compression function.

- Other features are the same as the horizontal type.

Major Specifications

Specifications of vertical compressor

| Type | PL-2000V | PL-3000V | PL-4000V | PL-5000V | |

|---|---|---|---|---|---|

| Compression method | Hydraulically-driven one-directional vertical compression | ||||

| Dimensions of formed product | Approx. 1,000 wide x 1,000 long x 1,000 high (mm) | ||||

| Weight of formed product | Approx. 200-350kg each | ||||

| Compression force | MAX810kN(83ton) | ||||

| Surface pressure | MAX0.81MPa(8.3kgf/cm2) | ||||

| Processing capacity | 2t/h | 3t/h | 4t/h | 5t/h | |

| Hydraulic pressure | MAX20.6MPa(210kgf/cm2) | ||||

| Electric voltage | 3ØAC200/400V | ||||

| Engine for hydraulic unit | One 37kW unit | One 45kW unit | Two 30kW unit | Two 37kW unit | |

| Oil cooler pump | 1.5 | 1.5 | 3.7 | 3.7 | |

| Oil cooler fan | 0.2 | 0.4 | 0.75 | 0.75 | |

| Packing specifications | Packing in rolled polyethylene film + binding using PP bands | ||||

Note 1: The dimensions and weight of bails differ after being formed depends on the materials processed. Note 2: The processing capacity was calculated assuming the apparent densitiy of collected materials to be 0.03 ton/m3. The density of bails after compression is 0.25 to 0.3 tons/m3.

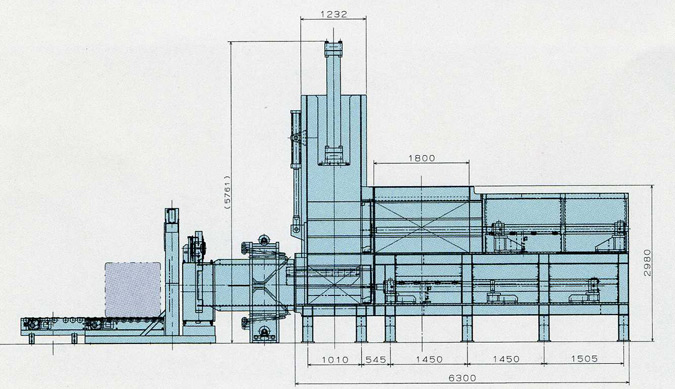

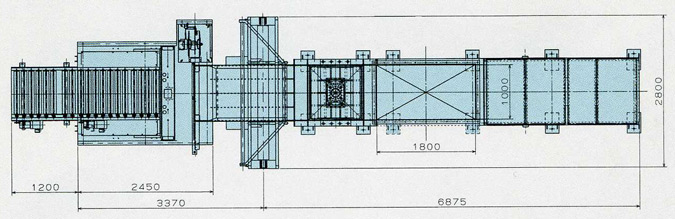

External drawing

Plan

Cross-section