HOME › Products › Recycle System › Fluorescent Lamp Crusher (NCR)

New Product

Fluorescent Lamp Crusher (NCR Series)

Prevents diffusion of mercury vapor and processes fluorescent lamps with high efficiency and safety.

KAMCHO's recycling technologies convert disposed fluorescent lamps into valuable resources.

This device promotes the recycling of waste since crushed fluorescent lamps are processed by Nomura Kohsan Co., Ltd.![]() using its unique systems, and recycled as raw materials for glass wool.

using its unique systems, and recycled as raw materials for glass wool.

Features

- Work is simple and easy as lamps are thrown in sideways.

- A multiple-task type that can process both linear and circular lamps

- The sealed structure eliminates fluorescent powder and ensures safety in the work environment.

- A compact structure with combined dust collector and mercury gas removing device

- Realizes high added-value recycling through crushing that does not destroy mouth rings

Specifications

| Type | NCR-40F | NCR-110F |

|---|---|---|

| Materials to be processed |

|

|

| Mechanical capacity |

|

|

| Dimensions of main unit (mm) | Approx. W2,400 x L1,780 x H2,700 | Approx. W3,600 x L1,780 x H2,700 |

| Weight | Approx. 800kg | Approx. 1,500kg |

| Engine | 1.35kW | 2.3kW |

| Power source | Tri-phase 200V power cable of 10m (With insertion plug for 3P grounding) |

|

| Coating |

|

|

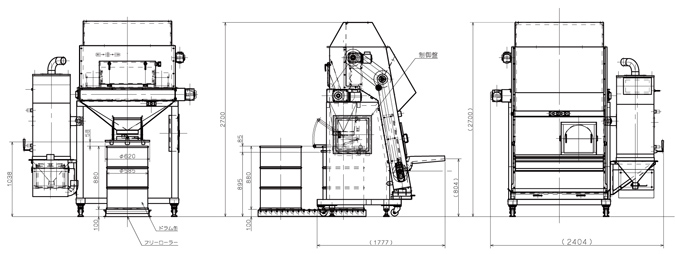

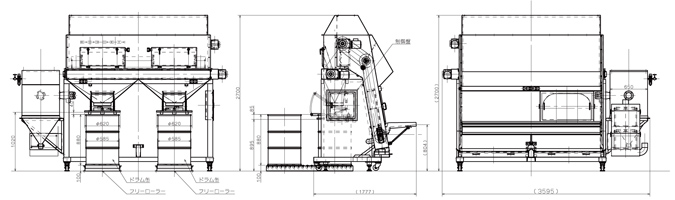

External view

NCR-40F

NCR-110F

Drums (Diameter of 600mm x Height of 900mm; capacity: 200 l), free-standing rollers and casters are options.

*Please use a mercury vapor protection mask when replacing the drums.

Used Fluorescent Lamp Recycling System

Crushed and washed glass recycled into residential insulation and raw materials for fluorescent lamps. Aluminum and metallic bases recycled into aluminum raw material. Mercury recovered from the wastewater after washing.

![[Waste fluorescent lamps]Mercury is contained in various types of fluorescent lamps; circle, straight, ball and compact lamps. A proper recycling process is necessary for each type of lamps.](img/img_flow_01.jpg)

![]()

![[Roasting process]Heating the sludge at 600 to 800 ℃ to vaporize the mercury:Multiple-hearthvertical furnace](img/img_flow_10.jpg)

![[Mercury recycling]:Condensation tower *Condensation:While the mercury vapor passes through the condensation tower, it is cooled down and condensed into the liquid mercury.*Refining:Recovered crude mercury is refined into high-purity metallic mercury (inorganic mercury.)](img/img_flow_11.jpg)

![[Glass recycling] High-quality cullet:Glass which accounts for more than 90 percent in weight of fluorescent lamps is recycled into glass raw material.](img/img_flow_14.gif)